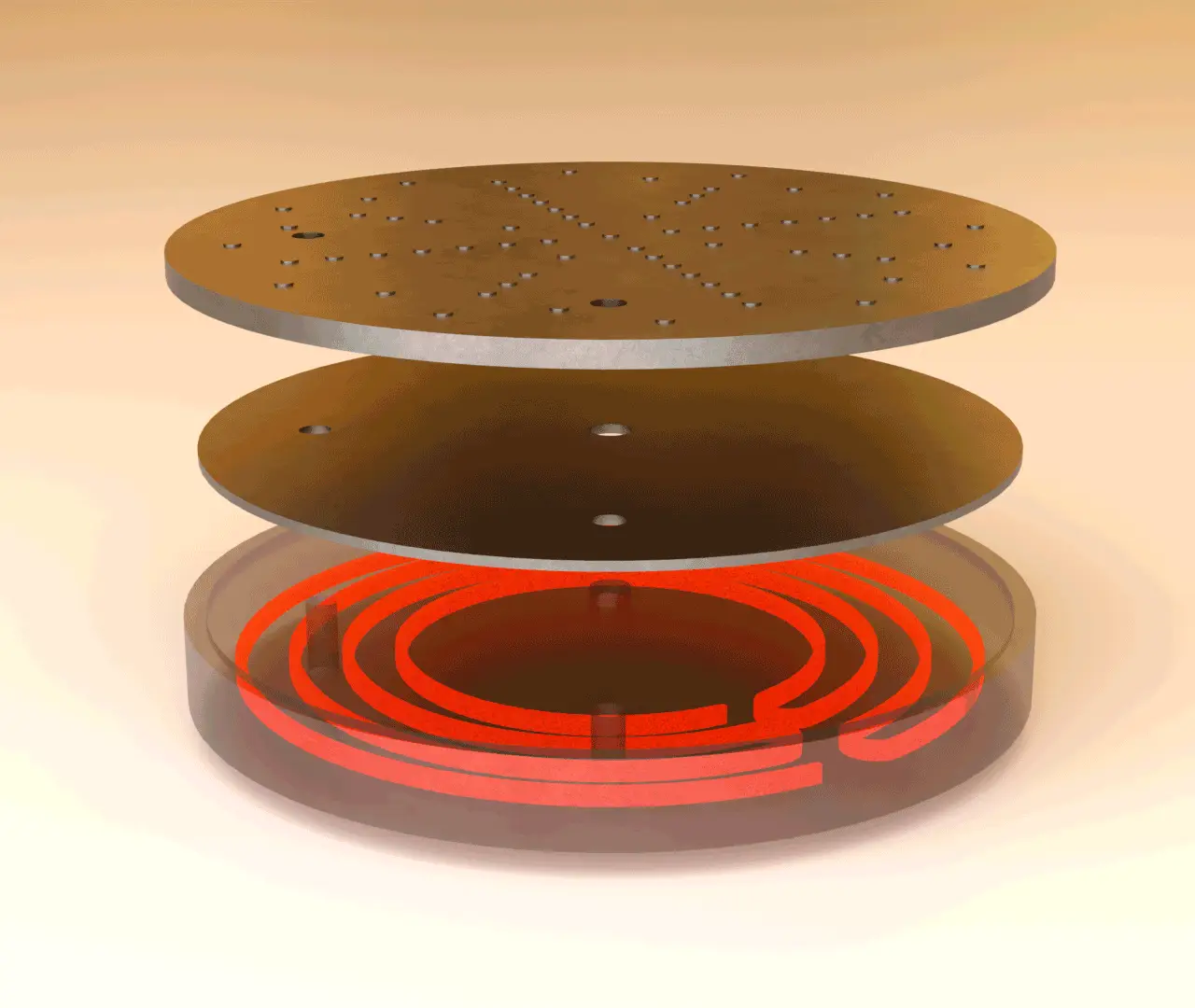

Thermal Leveler

Conductive Billet

Home | Products | Ceramics | Heaters, Electrostatic Chucks and Modules | Thermal Levelers

Description

Improve semiconductor process yield with greater thermal uniformity.

Improved temperature uniformity from the thermal leveler conductive billet results in better yield in wafer processing applications, faster temperature stabilization, and improved throughput.

Momentive Technologies fully passive solution with integrated TPG® also enables simpler designs and more corrosion resistant materials. Typical applications include high temperature thin film processing like CVD, ALD or PVD.

Validation of the concept

- Two 8” single zone stainless steel heaters were constructed with the same heater pattern; one with integrated TPG®, and one with a standard stainless steel configuration.

- A direct comparison revealed more than 2x improvement in TPG® heater surface thermal uniformity.

- A similar improvement level was predicted by computer modeling for a 12” stainless steel heater (for both single and double zone design).

- Azimuthal variations were eliminated (illustrated with the purple and red square locations in images.

Single Zone Heater (no TPG®) @1.65kW

| Tmax | 599°C |

| ΔT | 64°C |

| ΔT / Tmax | +/- 5.2% |

| StdDev / Avg | 2.2% |

Identical heater design (with TPG®) @1.65kW

| Tmax | 589°C |

| ΔT | 39°C |

| ΔT / Tmax | +/- 3.5% |

| StdDev / Avg | 1.0% |

Thermal uniformity is improved passively, using TPG®

- Thermal Pyrolytic Graphite (TPG®) is encapsulated in a metal billet, enabling greater uniformity for heating and cooling applications.

- TPG® material properties are ideal for thermal balancing across a surface (thermal conductivity of ~1700 W/mK in-plane, ~10 W/mK out of-plane).

Easily integrated into existing heater designs; flexible for other thermal uniformity and transport applications

- The conductive billet can be machined on the top surface (gas channels, mesas, lift pins) and bottom surface (heating or cooling channels), welded, and brazed.

- The conductive billet enhances the thermal uniformity of all heater designs and is compatible with single-zone and multi-zone.

- Solutions available in aluminum and austenitic stainless steel.

- Thermal uniformity benefits are also possible for cold plates or cooling applications.

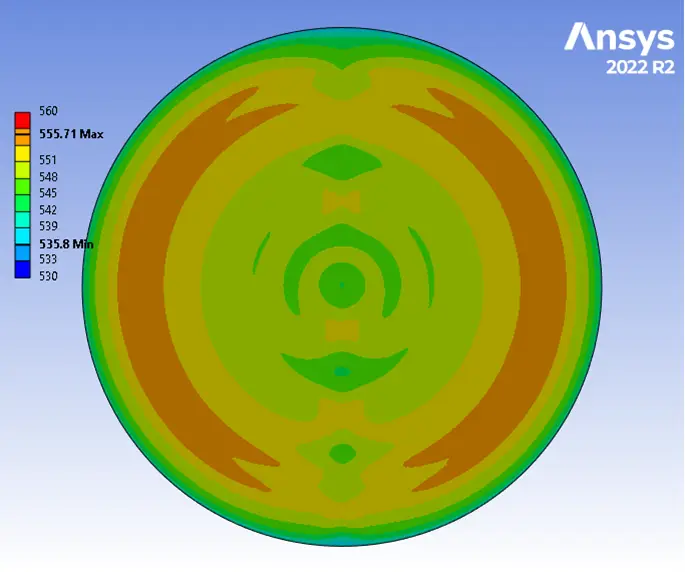

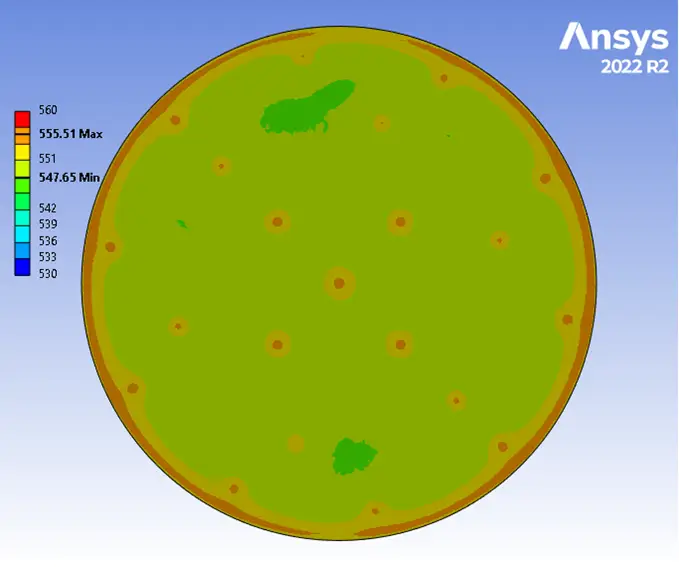

Design optimization supported by in-house thermal-mechanical computer modeling

- The computer model was validated with the manufactured heater prototypes.

- The model can be used to estimate expected thermal uniformity improvements for new designs.

- The adjacent figures show an estimated 2x improvement in thermal uniformity predicted by the model when comparing a 12” two zone stainless steel heater with and without TPG®.

Simulated temperature profiles of 12″ two-zone heaters with (right) and without (left) TPG